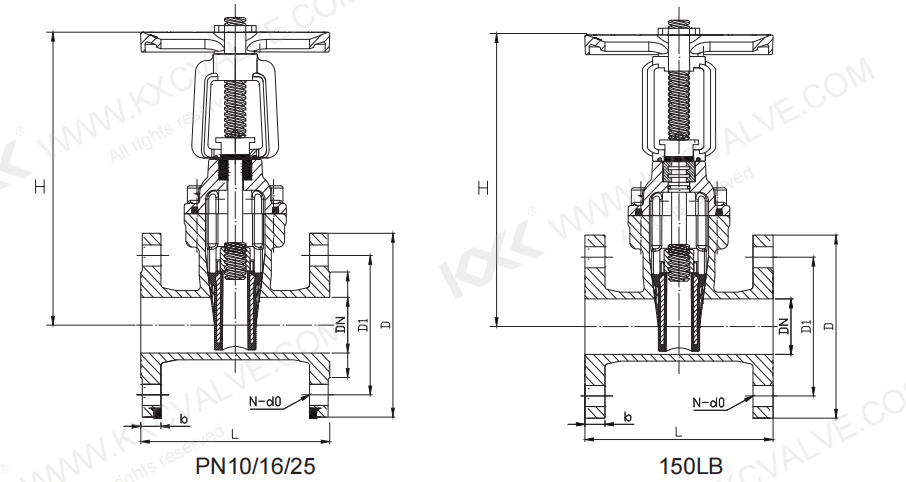

os&y Gate Valve Introduction

os&y resilient seat gate valve made of speclal rubber elastlcly full wrap-plece valve structure, and the general absence of gate leakage or rust compared to other phenomena. Overcome their common seal bad, elastic fatigue, wear rubber aging and Seal�ing ruts and other defects、 Produced by ths elastic saeling full compensation of small quantities of deformation to achieve a good sealing effect. It can be widely used in water supply, petrochemical, metallurgy, shipbuilding, food, pharmaceuticals and energy systems and other fluid line is used as a regulator and shut-off devices.

os&y gate valve resilient seat gate valve Features

1. The overall package of plastic: the spool and the latest high-performance rubber vulcanization technology overall coating. laminating are tight. accurate geometry, rellable sealing and long service life.

2. Light weight: body ductile iron material, gate valve to reducs weight than tha average 25%, easy installation and maintenance; gate valve maximum opening helght is generally low 60mm ~ 280mm, can be Installed where space is llmited.

3. Flat style seat: The bottom of the pipe the same flat style seat design, does not produce debris accumulation, flow channel unimpeded and reliable sealing.

4. Corrosion resistance: the valve cavity using non-toxic epoxy powder coating, inner parts mining copper alloy and stainless steel to prevent corrosion and rust.

5. The three 'O' seal: the use of the stem seal O-ring seals, friction is small, lightweight and watertight gwitch.

| SIZE | D | D1 | L | H | n-d | b | ∅ |

| DN | in | 10 | 16 | 25 | 150LB | 10 | 16 | 25 | 150LB | DIN | BS | ASME | 10/16 | 150LB | 10 | 16 | 25 | 150LB | 10 | 16 | 25 | 150LB |

| 50 | 2 | 165 | 150 | 125 | 120.7 | 150 | 178 | 177.8 | 290 | 295 | 4-19 | 4-19 | 4-19 | 19 | 14.3 | 160 |

| 65 | 2.5 | 185 | 180 | 145 | 139.7 | 170 | 190 | 190.5 | 325 | 325 | 4-19 | 8-19 | 4-19 | 19 | 15.9 | 160 |

| 80 | 3 | 200 | 190 | 160 | 152.4 | 180 | 203 | 203.2 | 365 | 365 | 8-19 | 8-19 | 4-19 | 18-19 | 17.5 | 200 |

| 100 | 4 | 220 | 220 | 235 | 230 | 180 | 180 | 190 | 190.5 | 190 | 229 | 228.6 | 425 | 425 | 8-19 | 8-22 | 8-19 | 18-19 | 22.3 | 200 |

| 125 | 5 | 250 | 250 | 270 | 255 | 210 | 210 | 220 | 215.9 | 200 | 254 | 254 | 510 | 510 | 8-19 | 8-26 | 8-22 | 18 | 24 | 22.3 | 260 |

| 150 | 6 | 285 | 285 | 300 | 280 | 240 | 240 | 250 | 241.3 | 210 | 267 | 266.7 | 580 | 580 | 8-23 | 8-26 | 8-22 | 19 | 24 | 23.9 | 260 |

| 200 | 8 | 340 | 340 | 360 | 345 | 295 | 295 | 310 | 298.5 | 230 | 292 | 292.1 | 740 | 740 | 8-23 | 12-23 | 12-26 | 8-22 | 20 | 24 | 27 | 330 |

| 250 | 10 | 405 | 405 | 425 | 405 | 350 | 355 | 370 | 362 | 250 | 330 | 330.2 | 895 | 895 | 12-23 | 12-28 | 12-30 | 12-26 | 22 | 27 | 28.6 | 400 |

| 300 | 12 | 460 | 460 | 485 | 485 | 400 | 410 | 430 | 431.8 | 270 | 356 | 355.6 | 1055 | 1055 | 12-23 | 12-28 | 16-30 | 12-26 | 24 | 22 | 27 | 30.2 | 400 |

| 350 | 14 | 520 | 520 | 555 | 535 | 460 | 470 | 490 | 476.3 | 290 | 381 | 381 | 1170 |

| 16-23 | 16-28 | 16-33 | 16-29 | 25 | 30 | 33.4 | 465 |

| 400 | 16 | 580 | 580 | 620 | 595 | 515 | 525 | 550 | 539.8 | 310 | 406 | 406 | 1350 |

| 16-28 | 16-31 | 16-36 | 16-29 | 28 | 33 | 35 | 465 |

| 450 | 18 | 640 | 640 |

| 635 | 565 | 585 |

| 577.9 | 330 | 432 | 432 |

|

| 20-28 | 20-31 |

| 16-32 | 29 |

| 38.1 | 465 |

| 500 | 20 | 715 | 715 |

| 700 | 620 | 650 |

| 635 | 350 | 457 | 457.2 | 1740 |

| 20-28 | 20-31 |

| 20-32 | 31 |

| 41.3 | 630 |

| 600 | 24 | 840 | 840 |

| 815 | 725 | 770 |

| 749.3 | 390 | 508 | 508 |

|

| 20-31 | 20-38 |

| 20-35 | 33 |

| 46.1 | 630 |

os&y gate valve body matieral

os&y gate valve have the threads external to the valve body. The gate valve stem is moving up when the valve is opening. os&y gate valve are usually made from cast or forged steel while non rising stem valves are more typically brass, bronze or cast iron.

Rising stem gate valves body under high pressure

Rising stem gate valves can be used in high pressure rating up to Class 2500 or up to 420 bar, while non rising stem gate valves are normally used for middle pressure rating.

Attention of Rising stem gate valves

In this way you can visually keep track of how far the valve is open. With a rising stem gate valve it is easy to tell if the valve is open or closed by looking at the amount of stem that is exposed. If the handle is flush with the pipe (no exposed stem), the valve is closed. If a lot of stem is exposed, the valve is open.

DIN BS API is the abbreviation of American Petroleum Institute. API was founded in 1919 and was the first national-level business association in the United States. An important task of API is to be responsible for the standardization of equipment used in the oil and gas industry to ensure the safe and reliable interchangeability of equipment used in the industry. API enjoys a high reputation in the United States and abroad. According to its technical standards for petrochemical and oil extraction machinery, it has been adopted by many countries. It is a petroleum machinery certification body recognized by the US Department of Commerce and the US Trade Commission. API certification mark also enjoys a high reputation in the international arena. Petroleum machinery wearing the API logo is not only considered to be of reliable quality but also of advanced technology.

DIN BS API standards are divided into three categories:

1. Petroleum equipment design and manufacturing specifications;

2. Recommended practices for the use and maintenance of petroleum equipment;

3. Recommended practices for drilling and strip production operations.